Sheet Metal Finishing

When it comes to the final process in metal fabrication, it’s not when a specific output or product achieves the shape and the form it needs – it’s when the finishing has finished and the overall product is polished.

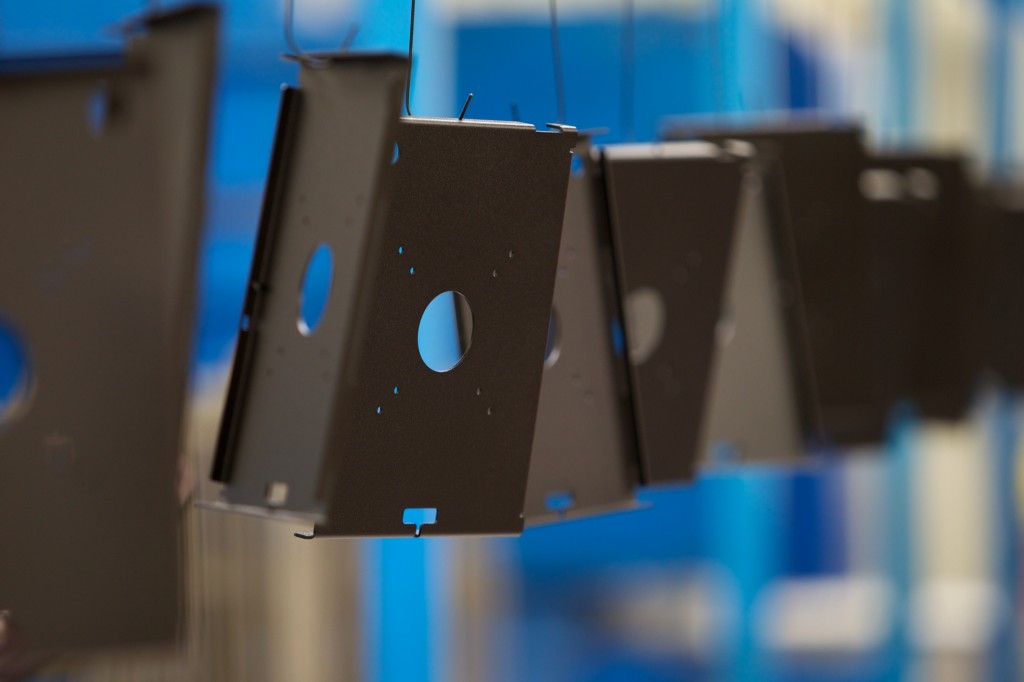

Sheet metal finishing is among the most sought services in the process. Instead of leaving the product as it is, several processes and procedures are done in order to improve, enhance, and develop the sheet metal.

There are many different types and kinds of sheet metal finishing, it can include the deburring or the rounding of the edges, metal plating, buff polishing, powder coating, sand blasting, and many more. With us here at Illinois Contract Manufacturing Experts, the sheet metal finishing you need will definitely be provided to you.

No matter how hard or how complex a certain sheet metal’s shape or form is, you can trust us to help you in terms of providing the final touch to it.

The Importance of Metal Finishing

But why is metal finishing considered as one of the most important parts of metal fabrication? How can metal finishing be an advantage to certain products, outputs, and semi-finished equipment? Metal finishing is the process of changing up and altering the exterior of the surface of the product or output and without it, the lifespan of each product or component would be shortened to half of what they should have.

Other than that, metal finishing is used by many different businesses and companies because of the following benefits they provide.

Enhanced Resistance

When a product or a specific output is finished, they are less likely to experience chipping, scratching, and even corrosion. The wear and tear process of steels and metals will not be as fast and as easy if they are finished.

On the contrary, metals and steels that are left without any type of treatment or resistance will corrode and be rusted easily, and their resistance would be weaker.

Improved Appearance

Other than the durability and the resistance that it provides, sheet metal finishing administers a better and a more improved appearance to the product. We’re not just talking about regular paint – finishing involves many different types and kinds.

Enhanced Efficiency

With finished metals and steels, they’ll be a lot easier to clean and to maintain. Compare it to an unfinished material where there’ll be a lot of bumps and rough areas and patches, sheet metal finishing would really be for the betterment of a certain product.

They’ll be more durable, they’ll have better and improved aesthetics, and they’ll be a lot easier to clean. You will not experience any type of problem with the physique and the overall exterior of your sheet metal as they’ll be coated.

Metal Finishing Types

There are many different types of sheet metal finishes but when you work with us here at Illinois Contract Manufacturing Experts, you can expect that we’ll be able to help you with a ton of different options including:

Powder Coating

In sheet metal finishing and even in other types of steel finishes, powder coating is one of the most popular and the most sought types of finishes because of the ideal promises it has with the products or the outputs.

Powder coating is done by spraying dry powder to the surface, which is released by pressure. Like how you imagine it, powder coating is like spraying of specialized powder on the surface of products and outputs.

And we here at Illinois Contract Manufacturing Experts concoct our own dry powder and we do not use solvents, making your products and your outputs safe!

Metal Plating

Have you ever wondered how some metallic products and components achieved the metal plate that they have? As a matter of fact, metal plating is among the most common and the simplest forms of finishing.

It involves a chemical bath coating the entire surface of the metal sheet or product. Other than the chemical bath, it also involves electrocuting the metal or the product inside the concoction and acts as the catalyst in the process.

Buff Polishing

If your item or your product requires a smooth finish, buff polishing is the finishing procedure that you need. Buff polishing is known for the creation of smoothened and non-textured finishes and is perfect for furniture and other household equipment.

Buff polishing is the process of applying a spinning cloth wheel that accomplishes the buffed polish for your sheet metals or other products and components.

Sand Blasting

Do you require a matte-textured finish to your steel or your metal? If so, then the process of sand blasting is what you need. Sand blasting or in other terms, beadblasting, is the finish where sand and other types of abrasives are applied to different products and outputs.

Using a pressure machine, the machine blasts a certain product with abrasives, coating it at a high rate of speed. Sand blasting is the most recommended type of finish for soft metals.

Metal Grinding

Need to achieve a smooth but textured feel to your metal? The metal grinding process that we offer here at Illinois Contract Manufacturing Experts will be the only answer you need. By using friction and/or compression to the finish, it results in an even and smoothened metal or steel surface.

You can expect us to perform these finishes to a wide spectrum of metals including brass, nickel, stainless steel, aluminum steel, mild steel, and many more.

Why Choose Illinois Contract Manufacturing Experts?

There are not a lot of manufacturers and fabrication companies out in the market capable of performing the sheet metal finishing procedures we do. Our experts and our professionals are all skilled in terms of a wide spectrum of finishes – whether you need help in producing a matte-textured product through sand blasting, or if you need the durability of powder coating, you can count on us!

Many companies have worked with us and they neither regretted nor were they disappointed with the results they offered!

Our core offerings and services at Illinois Contract Manufacturing Experts includes, but is not limited to, the following below:

Whatever industry you might be in – whether you are in the commercial, retail, manufacturing, and in the automotive or the aerospace industry, you can count on us and our specificity in the products and the outputs we provide.

We service multiple cities throughout the state of Illinois. We provide all the services listed above, and much more in every city throughout Illinois.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.