Laser Cutting Process

If you’re well-versed in the industry of manufacturing and metal fabrication, then you must have an idea or two about the different processes and different methods of cutting. For starters, cutting is a subtractive process involving all kinds of materials from wood, plastic, gemstones, glass, steel, and metal.

There are plenty of different traditional cutting procedures such as flame cutting, water jet cutting, plasma cutting, laser cutting, and the like. Even if the term “laser cutting” sounds a bit too much futuristic, it is actually widely used now and it’s deemed as the primary method of cutting in manufacturing.

But how does the laser cutting process work? Will it involve an operator? Or would it work independently through the programming of machines and technology? We here at Illinois Contract Manufacturing Experts are more than happy to help you in learning and in figuring out how the laser cutting process works, as well as a few bits of why we have been deemed as the best and the most dependable manufacturer in the state.

Understanding How Laser Cutting Works

Before we get to the main idea on how laser cutting works, it is imperative to understand and comprehend what it is as well as what factors and things are involved; this allows pure knowledge to run and better see the implications and the results that laser cutting can get.

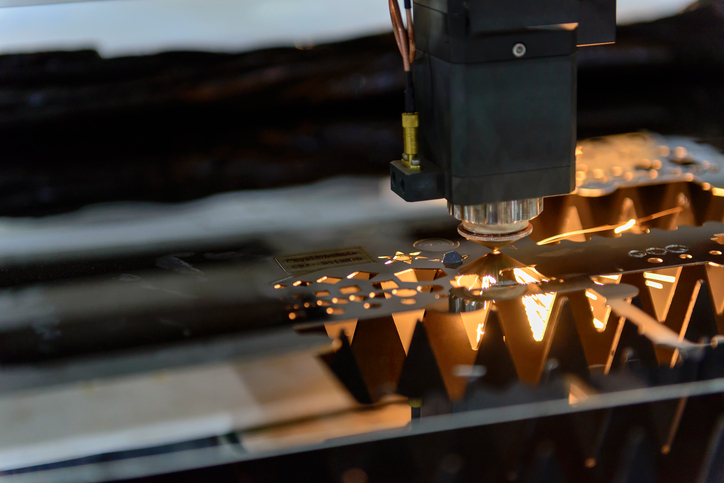

The laser cutting process is a non-contact, thermal-based type of process where a laser beam is focused directly on the material, exposing it to the combined heat and pressure, doing the cut.

Other than cutting it, the laser beam can also be used to provide different types of services to a given workpiece or material such as:

- Laser Drilling — the punching of holes to a certain product or material

- Laser Engraving — the method in which the laser will be programmed “not to cut” through the material but to leave a long-lasting mark

- Laser Marking — or the discoloring of the surface of the area

Before the Cutting

Before the exact procedure, programmers and engineers will be programming the movement and the entire project of the laser, making it the way that it should be followed. For instance, if you are looking to cut a metal sheet into different shapes, it will be pre-programmed via software and will be fed to the CNC or the computer numerically controlled laser cutting machines.

From here, it’s easy-going – you’ll load it up to the machine and it will do everything for you. Just sit back, watch, and if you’re going for mass production, you need to regularly and attentively clean and maintain your machine.

Our Laser Cutting

Akin to the applications of the laser cutting process, ours here at Illinois Contract Manufacturing Experts only apply to steel and metal cutting which are primarily used for metal fabrication as well as contract manufacturing.

The laser cutting process you can ask us to work on for you can help in producing many different kinds of outputs, from formed and shaped metal sheets, artwork, frames and grills, and a lot more.

Why Companies Use Laser Cutting

Because of its effectiveness and its efficiency, companies shifted to using laser cutting and considered it as their primary cutting procedure. Thanks to these benefits, the laser cutting process has been known to be the most effective and the most flexible type of cutting procedure in manufacturing.

Consistency in Production

If you need to produce goods, products, and other types of components consistently, you could never go wrong with a laser cutting process. The input that you would be programmed into the machine would be what it’s going to produce – and it’s going to be the same exact copies of what you need.

There rarely are changes with the outputs and the overall look of the product. Rest assured that the products that you would be in dire need of would be what we will produce.

Safer

Since the laser cutting process involves the use of machines, there’ll be little-to-no need for the intervention of machine operators and experts, making it safer and more secure than the average and the regular modes of cutting.

If you care for the welfare and for the safety of your people and your employees, then laser cutting is no doubt what you need.

Higher Productivity

You can actually pass some of the projects and the responsibilities to us here at Illinois Contract Manufacturing Experts and we’ll still get you exactly – and even better – the final product you need. We will definitely be working towards helping you with better and higher productivity and you can count on us that we will be matching the quality that you are looking for.

Better Quality

Other than the consistency of all your final outputs, your products, materials, parts, and components will come out in the best and in the highest quality that you can expect. In comparison to the regular and traditional metal and steel cutting methods, laser cutting is accurate and precise – from the cuts and the spots, and even the pressure that it works on.

Your Decision Matters

If you are looking for a better and brighter tomorrow for your business, working with us must be your top priority. We have never failed any of our clients in providing the utmost and high quality of production. Using our advanced tools, equipment, and technologies, we are able to guarantee not only the highest quality of products and outputs but also the efficiency and the big positive impact we can have for your business.

You can always count on us here at Illinois Contract Manufacturing Experts as you go in terms of improving and maximizing the efficiency of your business. Work with us and receive the most accurate and the most precise of the laser cutting process you need.

No matter how thick or how hard a certain material is, we have our ways to work on it. Trust us and our laser cutting processes just like how other businesses and companies have!

Our core offerings and services at Illinois Contract Manufacturing Experts includes, but is not limited to, the following below:

Whatever industry you might be in – whether you are in the commercial, retail, manufacturing, and in the automotive or the aerospace industry, you can count on us and our specificity in the products and the outputs we provide.

We service multiple cities throughout the state of Illinois. We provide all the services listed above, and much more in every city throughout Illinois.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.