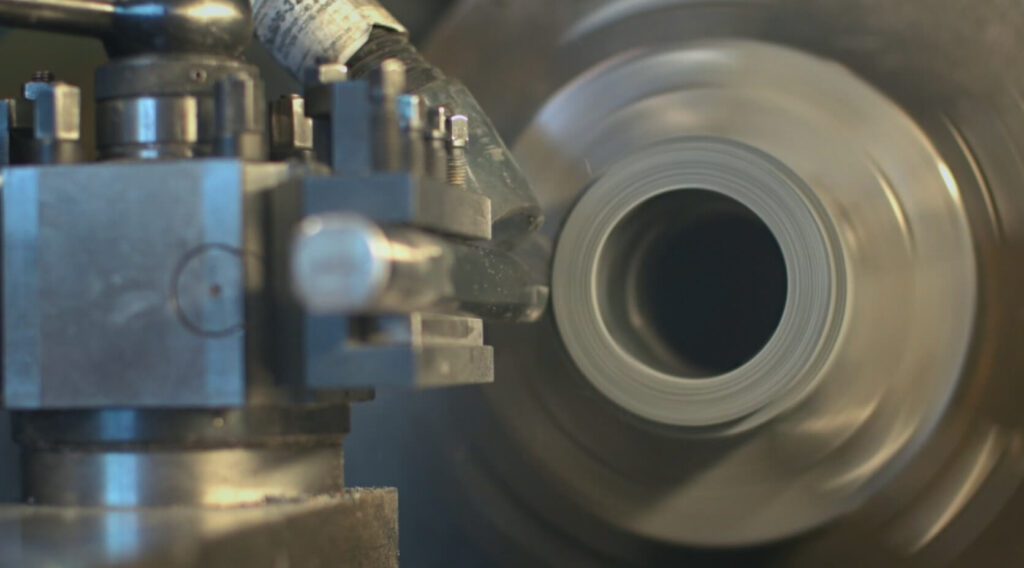

CNC Machining

Do you know what CNC machining is and how it became one of the most important processes in the manufacturing and in the metal fabrication industry? In this post, we will be discussing what CNC machining is, how it’s going to be better for your business, and why you need help from the manufacturers and the fabrication companies that practice it.

Dissecting CNC Machining

In understanding what CNC machining is, let’s first look at the two words separately. CNC stands for computer numerically controlled which basically means that machinery and equipment would not anymore require the supervision of a worker or a laborer.

CNC machines usually just need the programs of actions needed in order for them to administer the work they can do.

Machining, on the other hand, is a manufacturing process that is usually subtractive; subtractive because most of its work involves removing or subtracting some of the elements or components of a material.

Therefore, CNC machining, as a whole, is a subtractive process that helps out in the manufacturing and in the metal fabrication industry. The pre-programmed software or movement of the equipment and the types of machinery is what controls the overall process.

And we here at Illinois Contract Manufacturing Experts can help you with the processes and the procedures you need with CNC machining. But first, let’s try to understand what CNC machining is in general.

How CNC Machining Works

So how does CNC machining work? What steps are involved? Contrary to popular belief, we are not yet in the most advanced of ages where machines would no longer need any kind of human interaction; and though that’s what CNC machining requires, the programming would still be required.

The process goes like this:

- Preparation of the Computer-Aided Design (CAD) model or the type of product that would be produced by the machine or the equipment;

- Conversion of the CAD model to a program that can be read by the CNC machine – it’s usually just in a pre-programmed state which looks like small keyboards;

- Setting of the controls and some of the factors of the CNC machine;

- Feeding of the program or the software to the machine to proceed to the process; and

- The execution of the operation

Few Notes to Remember

Even with CNC machining, some of the work would still be needed from us humans because there are things that robots and machines can’t do that we can. In fact, here are a few points to remember about CNC machining.

Maintenance of the Machines is Needed

Even if it’s a self-sustaining type of machine to the point that you can leave it as it is and it’s still going to be producing the output or the product that has been pre-programmed, it would still need to be properly maintained.

As CNC machines, they’re expected to do the heavy-duty type of work, and therefore, they would be used up and there can be dirt that’s lurking around. A few instances of cleaning and tidying up would be good in order to keep the machine at its full capacity.

Programming Needs to be Done

One of the most important things in the CNC machining process is the programming of the software. This will be the backbone of everything – from the movement of the machines to the parts, components, and semi-finished equipment that would be produced and manufactured.

If you want the most trusted and the most dependable company with experienced programmers, then it’s no doubt that we at Illinois Contract Manufacturing Experts are the company you have been looking for.

All our programmers and our engineers are heavily-experienced and dedicated to their work. In fact, their vicious programming is the reason for the success of many different companies and manufacturers in the state.

It is Fully Automated

It is important to note that the productions of the parts of the machines are pre-programmed and it’s fully automated. For instance, the dimensions, the shape, and the exact form of the products would be dictated by the program and that’s what the machine is going to follow.

Thus, it leaves your operators no choice but to work on whatever has been programmed – should there be any type of change, it would be done manually or the programming would have to be modified.

We Have a Wide Range of Machines

Here with us at Illinois Contract Manufacturing Experts, you can expect that the types of CNC machines we have will never fall short to what you expect. As a matter of fact, we have invested in the best and the most advanced types of machines making it possible for us to multi-task.

You can work with us if you need the service of CNC milling equipment, CNC turning equipment, cutters, press brakes, and many more!

The Number One Manufacturer and Metal Fabrication Company

We would not be deemed and known as the best metal fabrication company and manufacturer in the state if it weren’t for the advancement of our machinery and equipment. With our CNC machining procedures and processes, we are able to produce and manufacture many different types of products and variations for our clients.

If they needed a good type of high mix, low volume manufacturing – or if they need large volume or mass production, we here at Illinois Contract Manufacturing Experts are always prepared to administer only the best and the highest quality of products and assemblies!

Why We’re the Best

Our expertise and mastery in the field overtook many other companies in the industry. With our continuous investment and drive to improve, we can be the metal fabrication company and the manufacturer that you will need for your production.

Need urgent and professional help and assistance in terms of producing and manufacturing metallic products, outputs, parts, components, and assembles? We at Illinois Contract Manufacturing Experts are one call away – and that means that you’re just a call away from experiencing world-class quality services at a reasonable and justifiable price! Give us a quick call and we’ll send you the estimate you need!

Our core offerings and services at Illinois Contract Manufacturing Experts includes, but is not limited to, the following below:

Whatever industry you might be in – whether you are in the commercial, retail, manufacturing, and in the automotive or the aerospace industry, you can count on us and our specificity in the products and the outputs we provide.

We service multiple cities throughout the state of Illinois. We provide all the services listed above, and much more in every city throughout Illinois.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.